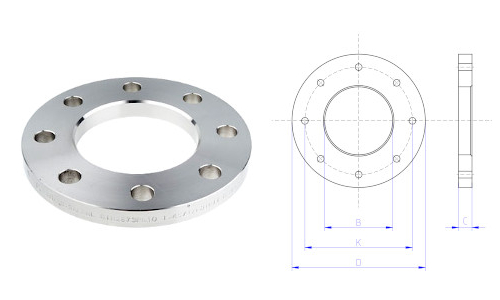

Loose plate flanges for removable joints of plastic pipelines

Technical Properties

| • Type | plate flange type 02 EN 1092 |

| • Galvanization | electrolytic |

| • Thickness | reduced for PE pipelines |

| • Upon request | hot-dip galvanization |

Steel galvanized flanges with reduced thickness are the standard solution for the connection of plastic pipes to pumps and operating devices or for the realization of pipelines that can be dismantled for maintenance purposes (i.e. dredging applications).

Product Range PN10

| DE/DN [mm/mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

B [mm] |

C [mm] |

|---|---|---|---|---|---|

| 32/25 | 115 | 85 | 4 x 14 | 42 | 8 |

| 40/32 | 140 | 100 | 4 x 18 | 51 | 8 |

| 50/40 | 150 | 110 | 4 x 18 | 62 | 8 |

| 63/50 | 165 | 125 | 4 x 18 | 78 | 10 |

| 75/65 | 185 | 145 | 8 x 18 | 92 | 10 |

| 90/80 | 200 | 160 | 8 x 18 | 108 | 10 |

| 110/100 | 220 | 180 | 8 x 18 | 128 | 12 |

| 125/100 | 220 | 180 | 8 x 18 | 135 | 12 |

| 140/125 | 250 | 210 | 8 x 18 | 158 | 12 |

| 160/150 | 285 | 240 | 8 x 22 | 178 | 12 |

| 180/150 | 285 | 240 | 8 x 22 | 188 | 12 |

| 200/200 | 340 | 295 | 8 x 22 | 235 | 14 |

| 225/200 | 340 | 295 | 8 x 22 | 238 | 14 |

| 250/250 | 395 | 350 | 12 x 22 | 288 | 16 |

| 280/250 | 395 | 350 | 12 x 22 | 294 | 16 |

| 315/300 | 445 | 400 | 12 x 22 | 338 | 20 |

| 355/350 | 505 | 460 | 16 x 22 | 376 | 22 |

| 400/400 | 565 | 515 | 16 x 26 | 430 | 22 |

| 450/450 | 615 | 565 | 20 x 26 | 517 | 24 |

| 450/500 | 670 | 620 | 20 x 26 | 517 | 24 |

| 500/500 | 670 | 620 | 20 x 26 | 533 | 24 |

| 560/600 | 780 | 725 | 20 x 30 | 618 | 25 |

| 630/600 | 780 | 725 | 20 x 30 | 645 | 25 |

| 710/700 | 895 | 840 | 24 x 30 | 740 | 28 |

| 800/800 | 1015 | 950 | 24 x 33 | 843 | 28 |

| 900/900 | 1115 | 1050 | 28 x 33 | 947 | 30 |

| 1000/1000 | 1230 | 1160 | 28 x 36 | 1050 | 30 |

| 1200/1200 | 1455 | 1380 | 32 x 39 | 1260 | 32 |

Other dimensions upon request

Product Range PN16

| DE/DN [mm/mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

B [mm] |

C [mm] |

|---|---|---|---|---|---|

| 32/25 | 115 | 85 | 4 x 14 | 42 | 8 |

| 40/32 | 140 | 100 | 4 x 18 | 51 | 8 |

| 50/40 | 150 | 110 | 4 x 18 | 62 | 8 |

| 63/50 | 165 | 125 | 4 x 18 | 78 | 10 |

| 75/65 | 185 | 145 | 8 x 18 | 92 | 10 |

| 90/80 | 200 | 160 | 8 x 18 | 108 | 10 |

| 110/100 | 220 | 180 | 8 x 18 | 128 | 12 |

| 125/100 | 220 | 180 | 8 x 18 | 135 | 12 |

| 140/125 | 250 | 210 | 8 x 18 | 158 | 12 |

| 160/150 | 285 | 240 | 8 x 22 | 178 | 12 |

| 180/150 | 285 | 240 | 8 x 22 | 188 | 12 |

| 200/200 | 340 | 295 | 12 x 22 | 235 | 14 |

| 225/200 | 340 | 295 | 12 x 22 | 238 | 14 |

| 250/250 | 405 | 355 | 12 x 26 | 288 | 16 |

| 280/250 | 405 | 355 | 12 x 26 | 294 | 16 |

| 315/300 | 460 | 410 | 12 x 26 | 338 | 20 |

| 355/350 | 520 | 470 | 16 x 26 | 376 | 22 |

| 400/400 | 580 | 525 | 16 x 30 | 430 | 22 |

| 450/450 | 640 | 585 | 20 x 30 | 517 | 26 |

| 450/500 | 715 | 650 | 20 x 33 | 517 | 26 |

| 500/500 | 715 | 650 | 20 x 33 | 533 | 26 |

| 560/600 | 840 | 770 | 20 x 36 | 618 | 31 |

| 630/600 | 840 | 770 | 20 x 36 | 645 | 31 |

Other dimensions upon request

Product Range PN25

| DE/DN [mm/mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

B [mm] |

C [mm] |

|---|---|---|---|---|---|

| 32/25 | 115 | 85 | 4 x 14 | 42 | 12 |

| 40/32 | 140 | 100 | 4 x 18 | 51 | 12 |

| 50/40 | 150 | 110 | 4 x 18 | 62 | 12 |

| 63/50 | 165 | 125 | 4 x 18 | 78 | 14 |

| 75/65 | 185 | 145 | 8 x 18 | 92 | 16 |

| 90/80 | 200 | 160 | 8 x 18 | 108 | 18 |

| 110/100 | 235 | 190 | 8 x 22 | 128 | 18 |

| 125/100 | 235 | 190 | 8 x 22 | 135 | 18 |

| 140/125 | 270 | 220 | 8 x 26 | 158 | 20 |

| 160/150 | 300 | 250 | 8 x 26 | 178 | 20 |

| 180/150 | 300 | 250 | 8 x 26 | 188 | 20 |

| 200/200 | 360 | 310 | 12 x 26 | 235 | 22 |

| 225/200 | 360 | 310 | 12 x 26 | 238 | 22 |

| 250/250 | 425 | 370 | 12 x 30 | 288 | 26 |

| 280/250 | 425 | 370 | 12 x 30 | 294 | 26 |

| 315/300 | 485 | 430 | 16 x 30 | 338 | 28 |

Other dimensions upon request

Reference Standards

| EN 1092-1 | Flanges and their joints – Flange Circular flanges for pipes, valves, fittings and accessories, PN designated – Part 1: Steel flanges |

| ISO 9624 |

Thermoplastic pipes for fluids under pressure – Mating dimensions of flange adapters and loose backing flanges |

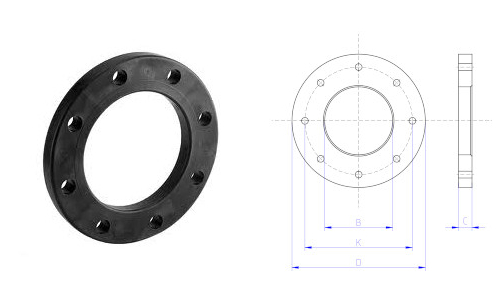

Technical Properties

| • Type | plate flange type 02 EN 1092 |

| • Inner ring | steel |

| • Coating | polypropylene |

| • Color | black |

Steel polypropylene covered flanges are used where the absolute resistance to corrosion of the flanged joint is a priority: the internal steel ring is in fact completely protected by the plastic layer thus avoiding any contact with the water present in the ground.

Product Range PN10

| DE/DN [mm/mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

B [mm] |

C [mm] |

|---|---|---|---|---|---|

| 32/25 | 115 | 85 | 4 x 14 | 42 | 14 |

| 40/32 | 140 | 100 | 4 x 18 | 51 | 16 |

| 50/40 | 150 | 110 | 4 x 18 | 62 | 16 |

| 63/50 | 165 | 125 | 4 x 18 | 78 | 19 |

| 75/65 | 185 | 145 | 4 x 18 | 92 | 19 |

| 90/80 | 200 | 160 | 8 x 18 | 108 | 21 |

| 110/100 | 220 | 180 | 8 x 18 | 128 | 22 |

| 125/100 | 220 | 180 | 8 x 18 | 135 | 22 |

| 140/125 | 250 | 210 | 8 x 18 | 158 | 26 |

| 160/150 | 285 | 240 | 8 x 22 | 178 | 27 |

| 180/150 | 285 | 240 | 8 x 22 | 188 | 27 |

| 200/200 | 340 | 295 | 8 x 22 | 235 | 28 |

| 225/200 | 340 | 295 | 8 x 22 | 238 | 28 |

| 250/250 | 406 | 350 | 12 x 22 | 288 | 31 |

| 280/250 | 406 | 350 | 12 x 22 | 294 | 31 |

| 315/300 | 460 | 400 | 12 x 22 | 338 | 34 |

| 355/350 | 512 | 460 | 16 x 22 | 376 | 39 |

| 400/400 | 580 | 515 | 16 x 26 | 430 | 43 |

| 450/500 | 678 | 620 | 20 x 26 | 517 | 45 |

| 500/500 | 678 | 620 | 20 x 26 | 533 | 45 |

| 560/600 | 790 | 725 | 20 x 30 | 618 | 50 |

| 630/600 | 790 | 725 | 20 x 30 | 645 | 50 |

Other dimensions upon request

Product Range PN16

| DE/DN [mm/mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

B [mm] |

C [mm] |

|---|---|---|---|---|---|

| 32/25 | 115 | 85 | 4 x 14 | 42 | 14 |

| 40/32 | 140 | 100 | 4 x 18 | 51 | 16 |

| 50/40 | 150 | 110 | 4 x 18 | 62 | 16 |

| 63/50 | 165 | 125 | 4 x 18 | 78 | 19 |

| 75/65 | 185 | 145 | 4 x 18 | 92 | 19 |

| 90/80 | 200 | 160 | 8 x 18 | 108 | 21 |

| 110/100 | 220 | 180 | 8 x 18 | 128 | 22 |

| 125/100 | 220 | 180 | 8 x 18 | 135 | 22 |

| 140/125 | 250 | 210 | 8 x 18 | 158 | 26 |

| 160/150 | 285 | 240 | 8 x 22 | 178 | 27 |

| 180/150 | 285 | 240 | 8 x 22 | 188 | 27 |

Other dimensions upon request

Reference Standards

| EN 1092-1 | Flanges and their joints – Flange Circular flanges for pipes, valves, fittings and accessories, PN designated – Part 1: Steel flanges |

| ISO 9624 |

Thermoplastic pipes for fluids under pressure – Mating dimensions of flange adapters and loose backing flanges |

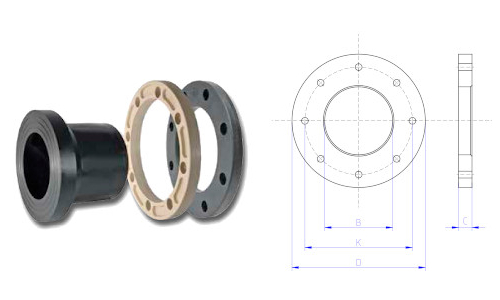

Technical Properties

| • Type A | PE100 stubend |

| PP flange | |

| • Type B | PE100 stubend |

| PP ring | |

| Steel/PP covered flange |

The antifluage kit is a particularly interesting flanged joint system made up of a PE100 stubend and a special polypropylene ring to contain it.

This solution totally reduces the deformation of the stubend over time due to the pressure applied by the flange and therefore avoids the need to periodically tighten the bolts as occurs in traditional systems.

Product Range PN10

| DE [mm] |

DN [mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

Type [-] |

|---|---|---|---|---|---|

| 40 | 32-40 | 150 | 100-110 | 4 x 18 | A |

| 50 | 40-50 | 165 | 110-125 | 4 x 18 | A |

| 63 | 50-60-65 | 183 | 125-145 | 4 x 18 | A |

| 75 | 60-65-80 | 198 | 135-160 | 8 x 18 | A |

| 90 | 80 | 198 | 160 | 8 x 18 | A |

| 110 | 100 | 219 | 180 | 8 x 18 | A |

| 125 | 100 | 220 | 180 | 8 x 18 | A |

| 140 | 125 | 252 | 210 | 8 x 18 | B |

| 160 | 150 | 285 | 240 | 8 x 22 | B |

| 180 | 150 | 285 | 240 | 8 x 22 | B |

| 200 | 200 | 340 | 295 | 12 x 22 | B |

| 225 | 200 | 340 | 295 | 12 x 22 | B |

| 250 | 250 | 419 | 355 | 12 x 26 | B |

| 280 | 250 | 419 | 355 | 12 x 26 | B |

| 315 | 300 | 478 | 410 | 12 x 26 | B |

Other dimensions upon request

Product Range PN16

| DE [mm] |

DN [mm] |

D [mm] |

K [mm] |

Holes [# x mm] |

Type [-] |

|---|---|---|---|---|---|

| 40 | 32-40 | 150 | 100-110 | 4 x 18 | A |

| 50 | 40-50 | 165 | 110-125 | 4 x 18 | A |

| 63 | 50-60-65 | 183 | 125-145 | 4 x 18 | A |

| 75 | 60-65-80 | 198 | 135-160 | 8 x 18 | A |

| 90 | 80 | 198 | 160 | 8 x 18 | A |

| 110 | 100 | 219 | 180 | 8 x 18 | A |

| 125 | 100 | 220 | 180 | 8 x 18 | A |

| 140 | 125 | 252 | 210 | 8 x 18 | B |

| 160 | 150 | 285 | 240 | 8 x 22 | B |

| 180 | 150 | 285 | 240 | 8 x 22 | B |

Other dimensions upon request

Reference Standards

| EN 1092-1 | Flanges and their joints – Flange Circular flanges for pipes, valves, fittings and accessories, PN designated – Part 1: Steel flanges |

| ISO 9624 |

Thermoplastic pipes for fluids under pressure – Mating dimensions of flange adapters and loose backing flanges |