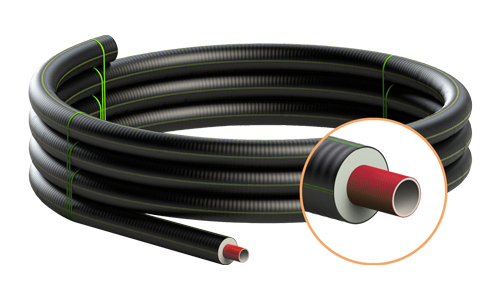

Pre-insulated flexyble PEX pipes for heating applications

Technical Properties

| • Peak temperature | +95 °C |

| • Operating temperature | +80 °C |

| • PUR thermal cond | 0.021 W/mK |

| • Operating Pmax | 6 bar |

| • Configuration | single or duo pipe |

Preinsulated flexible pipe systems made of cross-linked polyethylene core pipe and polyurethane insulation for district heating applications at low temperatures.

Advantages of HeatFlex system include: quick and convenient installation, narrow pipe trench and tight bending radius of the flexible bonded system.

HeatFlex carrier pipe is made of PEX-a SDR11 with oxygen barrier guaranteeing maximum pressure of 6 bar at 80 °C continuous working temperature.

This highly efficient pipe system boats an outstanding thermal conductivity value λ = 0.021 W/mK. In order to reduce the heat losses, a second insulation series with higher level of insulation is available too.

HeatFlex is the best solution for:

- Revamping of residential heating systems with underground hot water distribution networks

- Small low temperature and pressure domestic networks

- Agricultural applications (biogas plants, biomethane plants, biomass plants, etc.)

- Buried water networks for residential or industrial cooling

Product Range

| HeatFlex MONO |

Service Pipe D x s [mm] |

Casing Pipe OD [mm] |

Coil LMAX [m] |

|---|---|---|---|

| 25/76 | 25.0 x 2.3 | 76 | 770 |

| 32/76 | 32.0 x 2.9 | 76 | 770 |

| 40/91 | 40.0 x 3.7 | 91 | 550 |

| 50/111 | 50.0 x 4.6 | 111 | 410 |

| 63/126 | 63.0 x 5.8 | 126 | 300 |

| 75/142 | 75.0 x 6.8 | 142 | 225 |

| 90/162 | 90.0 x 8.2 | 162 | 150 |

| 110/162 | 110.0 x 10.0 | 162 | 150 |

| 125/182 | 125.0 x 11.4 | 182 | 86 |

Product Range DUO

| HeatFlex DUO |

Service Pipe OD x s [mm] |

Casing Pipe OD [mm] |

Coil LMAX [m] |

|---|---|---|---|

| 25+25/91 | 25.0 x 2.3 | 91 | 550 |

| 32+32/111 | 32.0 x 2.9 | 111 | 410 |

| 40+40/126 | 40.0 x 3.7 | 126 | 300 |

| 50+50/162 | 50.0 x 4.6 | 162 | 150 |

| 63+63/182 | 63.0 x 5.8 | 182 | 86 |

| 75+75/202 | 75.0 x 6.8 | 142 | 80 |

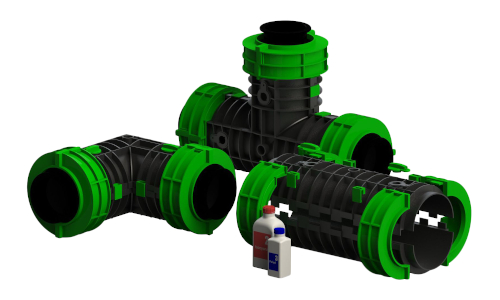

Fittings

HeatFlex pipes are connected using press or clamp connectors of different configurations (weld adaptors, couplers, elbows, tees).

HeatFlex pipes are connected using press or clamp connectors of different configurations (weld adaptors, couplers, elbows, tees).

The installation of the press connector requires the pipe end to be expanded before placing the metal insert into the pipe; this is followed by the compression of the outer sleeve onto the pipe’s outer surface with use of an industry-standard PEX press tool.

To install the clamp connector no need for pipe end to be expanded is required: the fittings installation is done with use of a conventional nut driver without the need for any special tooling.

Insulation of the Joints

The foaming of pipe joints is made with insulation shells of different configurations:

The foaming of pipe joints is made with insulation shells of different configurations:

– straight piece

– elbow 90°

– tee branch

The sealing of the joint against water and humidity penetrations is guaranteed by special lateral gaskets perfectly fit to the external corrugated casing of the pipe.

These insulation shells are quick and easy to install without the need for special tooling.

Reference Standards

| ZG 200-1 | Flexible pre-insulated pipe systems for district heating networks with bonded thermoplastic service pipe |

| EN 15632-2 | District heating pipes – Pre-insulated flexible pipe systems – Part 2: Bonded plastic service pipes – Requirements and test methods |

| EN 15875-2 |

Plastics piping systems for hot and cold water installations – Crosslinked polyethylene (PE-X) – Part 2: Pipes |