Flexible pre-insulated reinforced plastic pipes for district heating at elevated temperatures and pressures

Technical Properties

| • Peak temp | +115 °C |

| • Seasonal op temp | +95 °C |

| • PUR thermal cond | 0.021 W/mK |

| • Operating Pmax | 10-16 bar |

| • Configuration | single or duo pipe |

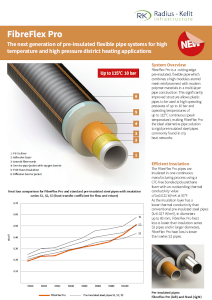

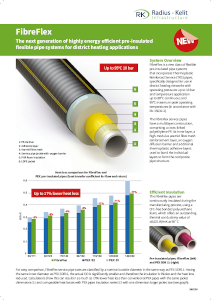

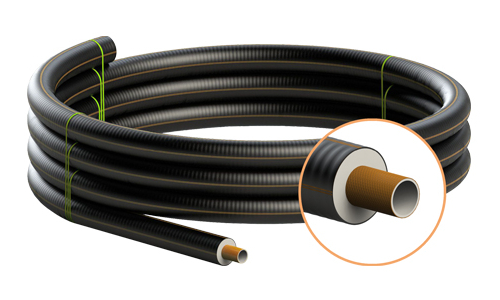

FibreFlex Pro is the new generation of flexible pre-insulated bonded pipes for district heating applications with plastic reinforced core pipes able to perform up to 115° peak temperature and 16 bar pressure.

FibreFlex Pro service pipes have a multilayer pipe wall construction, comprising a cross-linked polyethylene PEX-a inner layer, a high modulus aramid fibre mesh reinforcement layer, an oxygen barrier and additional high temperature resistant thermoplastic adhesive layers used to bond the individual layers to form the composite pipe structure.

FibreFlex Pro pipes are continuously insulated during the manufacturing process using a CFC free bonded polyurethane foam with an outstanding thermal conductivity value of 0.021 W/mK. The product range finally includes two insulation classes with different wall thickness of polyurethane foam in order to comply to any insulation requirement due to different outside temperature conditions.

FibreFlex Pro is the best solution for:

- Revamping of industrial heating systems with underground hot water distribution networks

- Small high temperature and pressure district heating networks

- Agricultural applications (biogas plants, biomethane plants, biomass plants, etc.)

- High pressure district heating networks in mountainous areas

Key Benefits

- FibreFlex Pro pipe systems are first of all flexible, so all the designing and installation issues are very simple. Especially the installation benefits merge wherever the FibreFlex Pro should be installed close to already existing pipelines or in very hard trench conditions between trees and buildings.

- Fibreflex Pro pipes can be used without any need of complex thermal expansion calculations: actually there is no need of thermal expansion compensators and this means fast and simple design.

- Preinsulated pipes systems FibreFlex Pro are generally supplied in long length coils or, wherever it is required for the pipeline extension, coiled on drums too. The pipes are usually supplied on lengths required by customers, dramatically reducing the quantity of joints.

- The FibreFlex Pro press jointing system overcomes the need to employ qualified on-site welding techniques normally associated with rigid district heating systems. Due to the extremely low number of joints, the time required to restore the insulation is thus completely negligible compared to the traditional systems mentioned above.

These longer continuous flexible pipe lengths, combined with an easy to install non-welded fittings solution, enables FibreFlex Pro pipes to be installed in long runs using narrow trenching techniques, offering significant on-site installation time and cost savings.

Product Range

| FibreFlex Pro MONO |

Service Pipe D x s [mm] |

Casing Pipe OD [mm] |

Coil LMAX [m] |

|---|---|---|---|

| 32/91 | 32.0 x 2.9 | 91 | 570 |

| 40/111 | 40.0 x 3.7 | 111 | 410 |

| ♦ 50/111 ♦ | 49.4 x 3.6 | 111 | 410 |

| ♦ 63/126 ♦ | 58.5 x 4.0 | 126 | 300 |

| ♦ 75/142 ♦ | 69.5 x 4.6 | 142 | 220 (440*) |

| ♦ 90/162 ♦ | 84.0 x 6.0 | 162 | 150 (300*) |

| ♦ 110/182 ♦ | 101.0 x 6.5 | 182 | 86 (170*) |

| 125/202 | 116.0 x 6.8 | 202 | 80 (160*) |

| 140/202 | 127.0 x 7.1 | 202 | 80 (160*) |

| 160/225 | 144.0 x 7.5 | 225 | 75 (150*) |

♦ PN16 available

* Maxicoil available on request (width 2.4 m)

Product Range DUO

| FibreFlex Pro DUO |

Service Pipe D x s [mm] |

Casing Pipe OD [mm] |

Coil LMAX [m] |

|---|---|---|---|

| 32+32/126 | 32.0 x 2.9 | 126 | 300 |

| 40+40/142 | 40.0 x 3.7 | 142 | 220 (440*) |

| ♦ 50+50/162 ♦ | 49.4 x 3.6 | 162 | 150 (300*) |

| ♦ 63+63/182 ♦ | 58.5 x 4.0 | 126 | 86 (170*) |

| ♦ 75+75/202 ♦ | 69.5 x 4.6 | 142 | 80 (160*) |

| ♦ 90+90/225 ♦ | 84.0 x 6.0 | 162 | 80 (160*) |

♦ PN16 available

* Maxicoil available on request (width 2.4 m)

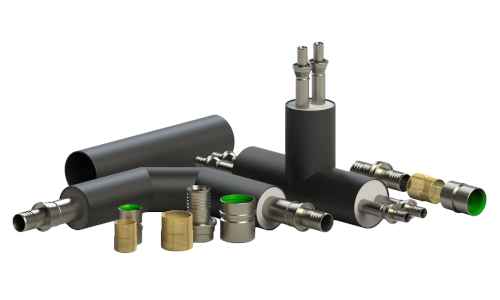

Jointing and Insulation of Joints

The jointing of flexyble preinsulated reinforced pipes FibreFlex Pro is made by mechanical axial compression couplers to be installed by means of hydraulic clamps.

The jointing of flexyble preinsulated reinforced pipes FibreFlex Pro is made by mechanical axial compression couplers to be installed by means of hydraulic clamps.

Those joints are made of 3 pieces:

– Internal steel male insert

– Polymer sleeve for high temperatures

– External steel ring

FibreFlex Pro is quick and easy to join using the abovementioned specially designed compression fittings, incorporating a unique polymer sleeve, which is inserted between the fitting’s outer sleeve and the service pipe. The steel insert is then easily fitted inside the pipe without any need for the pipe end to be expanded before the connection. This provides a robust and very secure joint.

The insulation of the joint is finally made with high density polyethylene or even better crosslinked polythylene shrinkable muffs as for the traditional steel preinsulated pipes.

Pre-insulated Fittings

Flexyble preinsulated reinforced pipes FibreFlex Pro have their own full range of steel preinsulated fittings with already welded steel male adaptor in order to avoid any further welding on worksite for a safer and faster installation.

Flexyble preinsulated reinforced pipes FibreFlex Pro have their own full range of steel preinsulated fittings with already welded steel male adaptor in order to avoid any further welding on worksite for a safer and faster installation.

Branch TEE pieces can be manufactured with different outlets:

– 45°, plain or parallel

– equal or reduced

To conclude, wherever it is not possible to bend the flexy pipes at required radius a complete range of preinsulated bends with both steel or plastic service pipe is available.

Reference Standards

| ZG 200-2 | Flexible pre-insulated pipe systems for district heating networks with bonded thermoplastic reinforced service pipe |

| EN 15632-2 | District heating pipes – Pre-insulated flexible pipe systems – Part 2: Bonded plastic service pipes – Requirements and test methods |